Adjustable and even

on all geometry

Evenness

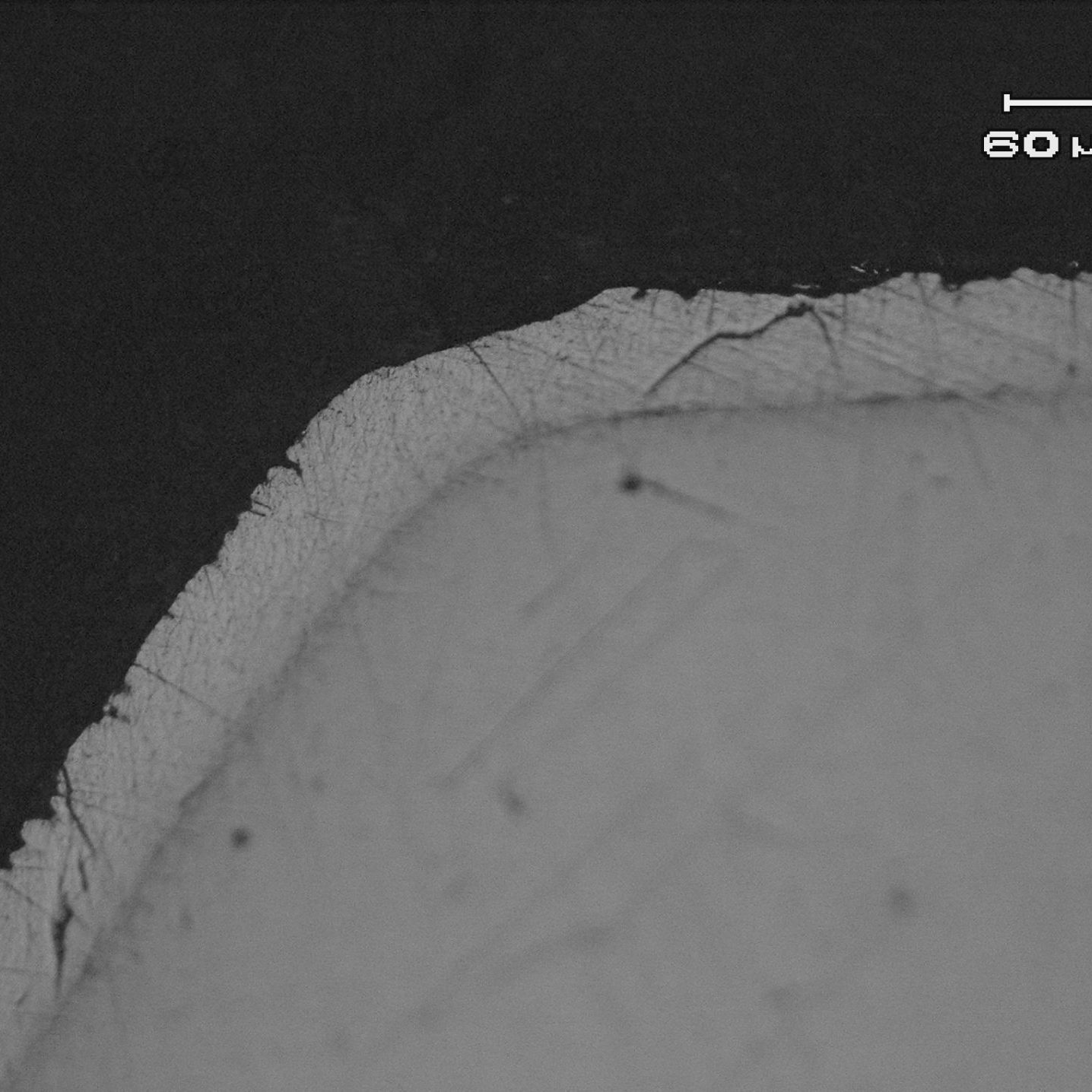

The coating forms in the gas phase of the zinc. An adjustable zinc-iron alloy of equal thickness is created.

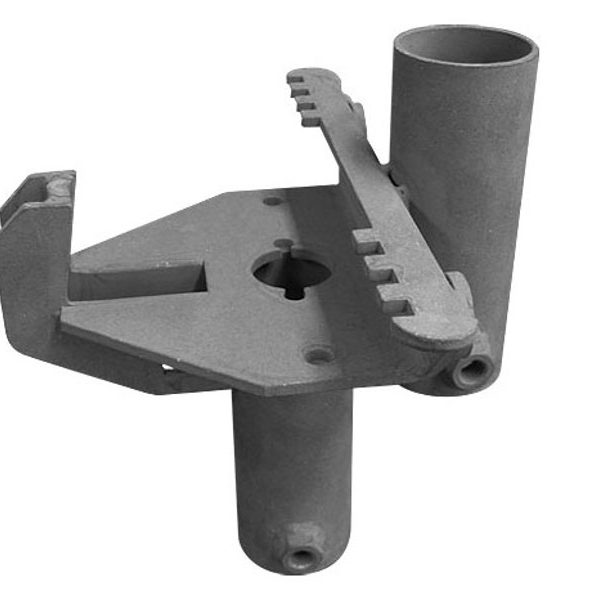

Highly profiled products such as threads, hexagon sockets or hollow spaces are covered by an even coating in the deepest and narrowest grooves.

Because diffusion galvanizing is a dry drum process, products with various geometric shapes can be treated.

The zinc layer follows exactly the contours of the screw thread, in hollow spaces or flat parts, regardless of whether these are thick, thin or vulnerable parts.

Reproducible and adjustable layer thickness

When sherardizing, it is possible to set the layer thickness from 10 µm to 100 µm. This is especially important for products with fits.

Products also receive the same layer thickness in repeat orders. The application of the product determines the minimum or maximum layer thickness.

SHERART’s specialists are happy to advise on this.

Why choose SHERART?

30 years of experience

Innovative

ISO 9001 & ISO 14001 certified

modern production company