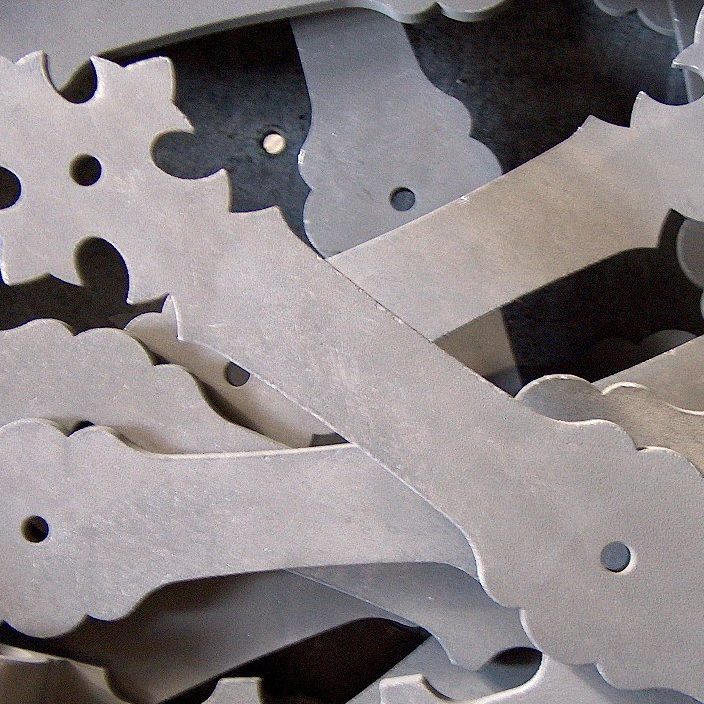

Base material

suitable for all basic materials

All types of iron and steel can be Sherardized-Diffusion Galvanized

At temperatures from 320°C to 500°C, the zinc bonds with the base material by diffusion. By using the right parameters, the special mechanical properties of your product are not affected.

Hardened, high-tensile steel

Sherardized products are guaranteed to be free from hydrogen embrittlement. This is particularly important for safety components and products made of hardened or high-strength steel.

Hydrogen embrittlement is caused by diffusion of atomic hydrogen in the steel. Sherardizing is a dry galvanizing process and the development of hydrogen embrittlement is therefore excluded from the process technology. Any hydrogen present in products will disappear during the heating process to 300°C before the zinc-iron alloy layers are formed.

Also due to the possible pre-treatment there is no chance of introducing hydrogen embrittlement, because this is carried out by blasting.

Diffusion galvanized HV connections with a steel quality up to 12.9 thus retain their strength and are protected against corrosion for a long time.

spring steel

Sherardizing does not create stresses in the material and hydrogen embrittlement and liquid metal embrittlement are excluded.

Sherardizing is therefore the pre-eminent galvanizing method for spring steel. Due to a reduced process temperature (320-380°C), spring steel can be diffusion galvanized without loss of properties.

Bars, made of spring steel up to a length of two meters, retain their resilient properties even under tension. Due to the flexible properties of the coating, there are no cracks in the coating as a result of resilient movements.

Sherardized spring steel products include very small springs for the mechanical engineering industry, compression springs for railway construction or train wagons, as well as for the automotive industry and bars that are rubberized after sherardization for agricultural mechanization.

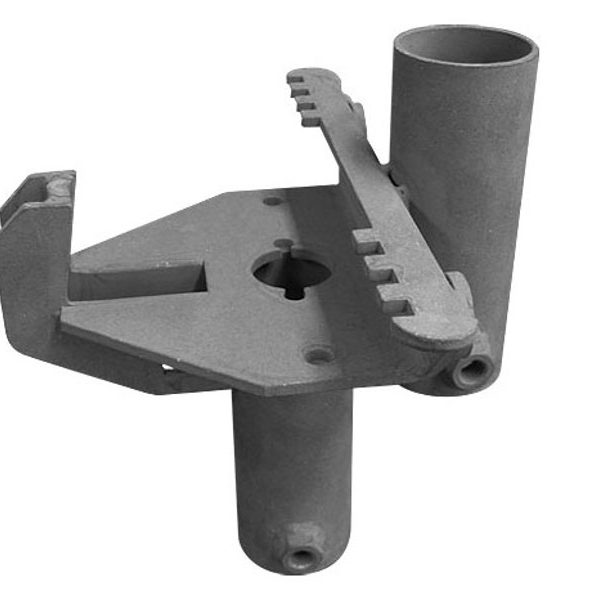

Cast Iron and Forged Steel

Uncontrolled growth of the zinc coating, such as with hot-dip galvanizing, is excluded during sherardization.

A diffusion galvanized coating is adjustable and even.

The Sandelin effect or liquid metal embrittlement does not occur.

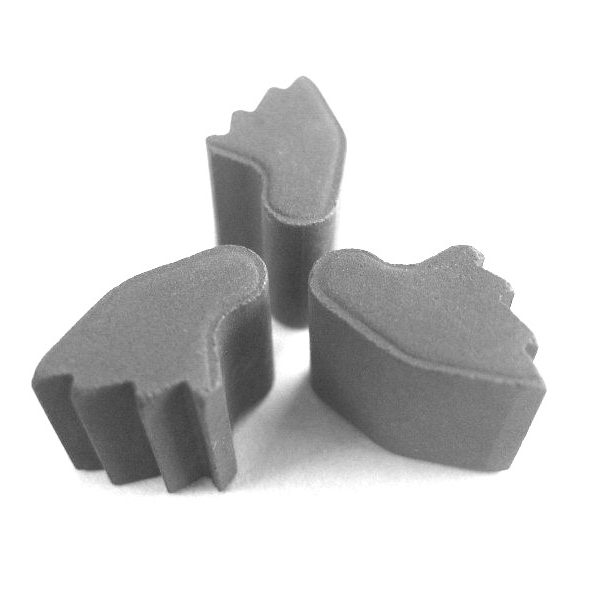

Sinter metal

The diffusion process occurs in the gas phase of zinc. This allows excellent sherardization of sintered metal products.

Stainless and austinite steels

Stainless steel, of course, does not need corrosion protection.

However, diffusion galvanizing produces a hard protective layer, which offers an excellent bonding base for, among other things, painting, vulcanising or glueing.

For example, stainless steel is painted to prevent contact corrosion. Stainless steel is a poor substrate for paint adhesion. This adhesion can be improved by sherardising the stainless steel beforehand. A sherardised top layer does provide an excellent bonding base.

If you have other metals, such as copper and nickel, please contact us to discuss the options.

Why choose SHERART?

30 years of experience

Innovative

ISO 9001 & ISO 14001 certified

modern production company